2000-24000BPH for 500ml complete water production line includes: 1. PET bottle blow molding machine 2. Water treatment system 3. 3 IN 1 water washing filling capping machine 4. Ink code printer / Laser code printer 5. PVC shrink sleeve / OPP hot glue / Adhesive sticker labeling machine 6. PE film packaging machine / Carton packaging machine 7. Automatic palletizer

How Bottled Mineral Pure Spring Still Water Is Making?

The machine combines washing, filling and capping three function in a body,used to produce plastic bottled mineral water,purified water machinery. The whole process is automatic, Filling way using the gravity or micro pressure filling, make the speed is faster and more stable, so with the same model our machine output is higher and more efficient. The CGF series bottled water filling line can achieve different output: 2000 / 4000 / 6000 / 8000 / 10000 / 12000 / 16000 /18000 /20000 / 24000 BPH.

The complete production line includes:

1. PET bottle blow molding machine

2. Water treatment system

3.3 IN 1 water washing filling capping machine

4. Ink code printer / Laser code printer

5. PVC shrink sleeve / OPP hot glue / Adhesive sticker labeling machine

6. PE film packaging machine / Carton packaging machine

7. Automatic palletizer

PET bottle blow molding machine

1. Blow moulding machine 1,000-24,000bph, and 0.25-2L PET bottles are available.

2. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle, etc.

3. The man-machine interface is highly automated and easy to operate.

4. The compact machine occupies a smaller area.

Water treatment system

1. Pre-treatment system (water tank / multi-medium filter / active carbon filter / ion exchanger / precious filter)

2. Membrane separation system (ultrafilter / nanometer filter / RO reverse osmosis system)

3. Electrodialysis device / Sterilization system (UV device, ozone device) product water tank and so on.

Bottle washing filling and capping machine

1. Water filling line production capacity is usual in 2,000-24,000bph, 0.20-2.0L PET bottles are available.

2. Water filling line can apply to fill natural spring water, purified water, still water into PET bottle.

3. Automatic water filling machine adopts rinsing, filling and capping 3-in-1 technology, PLC control, touch screen. It is mainly made of SUS304/ SUS316.

Blow Dryer

1. This machine installed after the filling machine.

2. This machine is used to removing the water outside the bottle surface, the blowing capacity can be adjusted through the button.

Laser Printer Machine

1. Good beam quality, TEM00 single mode output, beam diameter 10mm after collimation, M2<1.3, beam divergence Angle 0.24mrad;

2. Main-oscillation power amplification technology without maintenance and pulse generation technology of seed light source;High reliability, average no fault

Automatic opp hot glue labeling machine

1. The machine can be used for various bottle types, such as: round bottle, flat bottle, and so on.

2. Labeling machine is controlled by PLC touch screen, all-electric eyes are using imported advanced configuration.

3. High speed, high accuracy, stable performance.

Automatic PE film shrink wrapping machine

1. PE film shrink wrapping machine is suitable for wrapping of such products as mineral water, bottles beer, drinks etc without bottom-tray (or with bottom-tray).

2. Working with PE shrink tunnel to pack the goods perfectly. The whole producing process adopt the Germany advanced technics.

Zhangjiagang Comark Packaging Machinery Co.,ltd

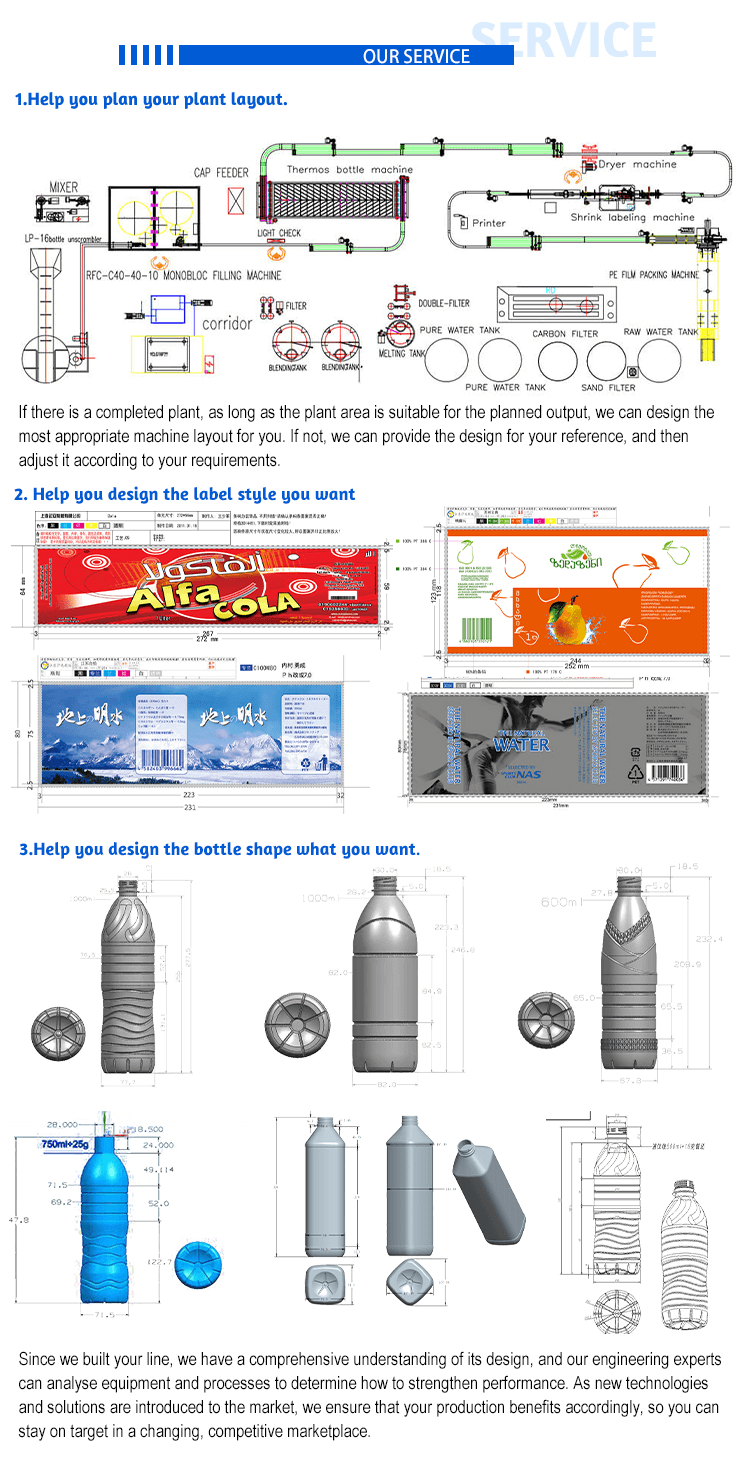

Zhangjiagang Comark Packaging Machinery Co., Ltd. is located in Zhangjiagang Economic Development Zone on the Bank of the Yangtze River. It has an international standard plant of 20000 square meters. It is an enterprise specializing in the R & D and production of beverage packaging machinery.Our team has more than 20 professional technical R & D personnel, 2 doctors of food science and technology, 5 masters and 15 senior professional engineers. This provides a favorable guarantee for the stable operation of the machine with high output. Our company's equipment is of high quality and can operate stably.We have more than 15 years of packaging experience. We understand market supply and demand and can provide market analysis, project budget, equipment and technology configuration, machines installation and operator training, etc. We always provide turnkey solutions and related services.