Application: still water, pure water, RO water, mineral water, sparkling water, alcoholic drinks, wine, etc. Suitable for: PET bottles Filling system: gravity filling Production capacity: 5,000BPH – 24,000BPH (500ml)

This automatic mineral water filling machine mainly used in the water filling operations, the three function of bottle washing, filling and capping are composed in one body of the machine, the whole process is automatic, it is conveniently turnked to adjust the machine to fill various types of bottles, the filling operation is faster and more stable due to the advanced filling valve technology, The famous brand programeed controller (PLC) is adopted to control the machine runs automatically. It is an ideal perferred equipment for beverage maker

Application

| Function :washing-filling-capping system | Control : PLC |

| Suitable :PET bottle with screw cap | Bottle Size :200-20000 ml |

| Filling System:Gavity Filling | Capacity :15,000 BPH For 500ml |

| Application :Still water ,Pure water ,RO water ,Mineral water and ect . | |

| Name :15,000 BPH Drinking water Filling Machine | |

| Model | CGF32-32-8 |

| Capacity :( for 500ml ) | 15,000 BPH |

| Suitable bottle shapes | PET Circular or square |

| Bottle diamater | 50-120 MM |

| Bottle Height | 150-320 MM |

| Compressor air | 0.3-0.7 Mpa |

| Washing Medium | Aspetic Water |

| Washing pressure | 0.06-0.2mpa |

| Application | Still water/Pure water/Mineral water |

| Power | 8.63 kw |

| Overall Dimensions | 3880*2200*2250 mm |

| Weight | 6000kgs |

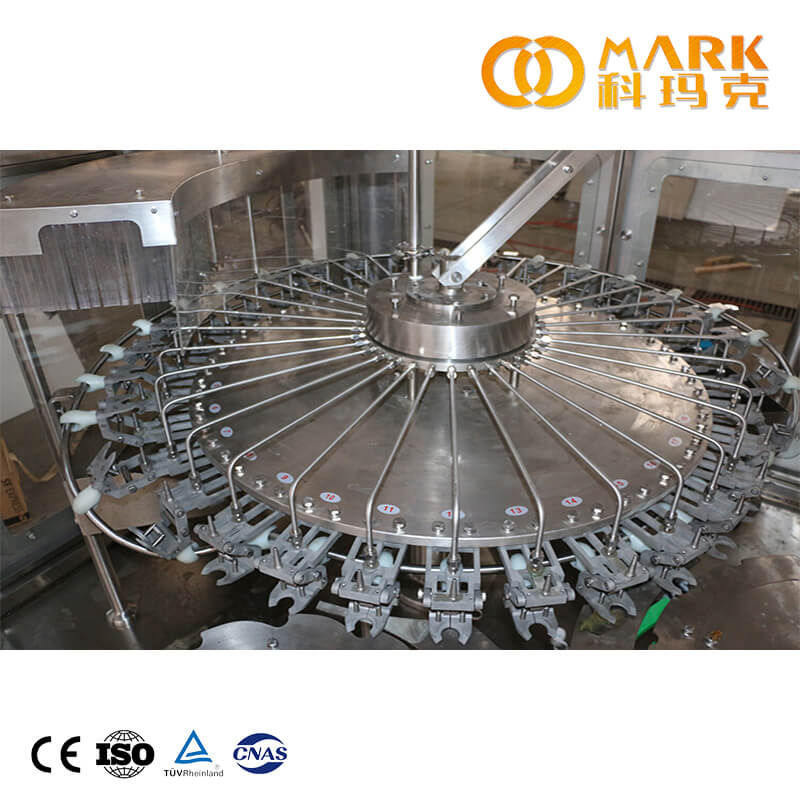

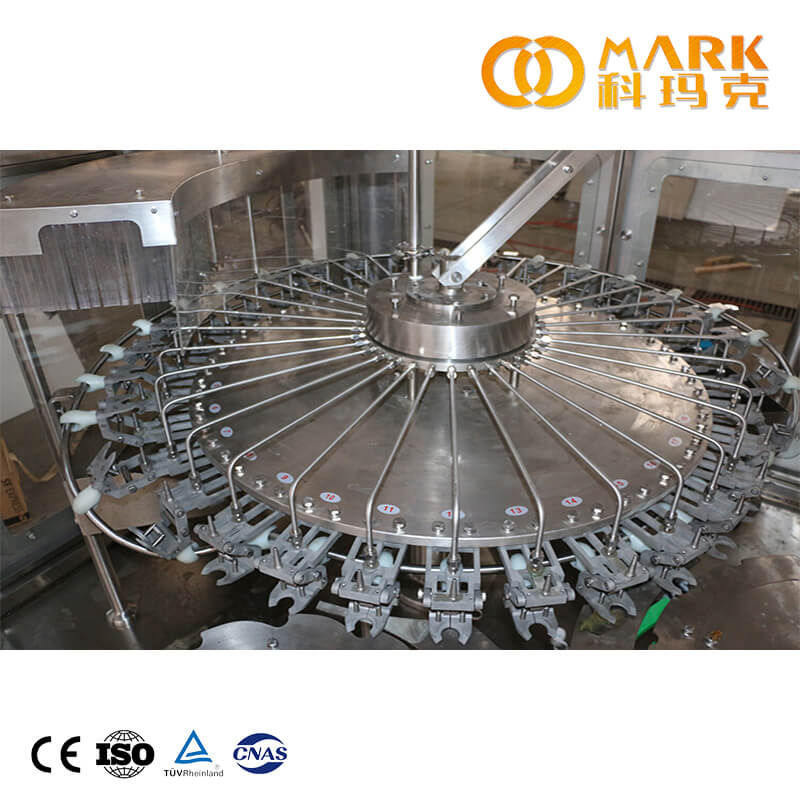

1)rinser

l. The rotary wheel is a fully stainless steel welded structure.

2. The machine applies unique overturning bottle clamp, which is an innovation of our company. This bottle clamp grips

bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle

clamp. Made of SUS304 stainless steel, this bottle clamp is hygienic and durable.

3. The high efficiency atomizing spay nozzle installed on bottle clamp is capable of cleaning any part of bottle inner wall,

and also saves rinsing water.

4. All sliding bushes of lifting device use Igus (Germany) anti-corrosion maintenance free bearing.

5. The rinser is driven by driving system positioned inside machine frame via gear transmission.

6. Transfer starwheel

7. Made of stainless steel of superior quality.

2) Filler

l. Rotary wheel fully made of stainless steel SUS 304.

2. Gravity filling method.

3. Filling valves are made of SUS316L.

4. Filling valves are reasonably structured with accurate filling.

5. Bottles go up and down in the function of cam through elevator, to process filling with contact to bottle-mouth.

6. Level of cylinder is controlled with float-ball.

3) Capper

Capper is the machine with highest precision, influence very much with the stability and reliability of the filling monoblock.

1.Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2.All 304stainless steel construction

3.Cap unscrambler, cap drop rail and capper

4.Minimum bottle crash during capping

5.No bottle no capping

Water Filling Machine Configurations

No | Item | Description |

1. | Rinsing pump | CNP-CHINA |

2. | Backflow pump | CNP-CHINA |

3. | Main motor+ reducer | ABB/SEW-Germany |

4. | Inverter | Mitsubishi-japan |

5. | Temperature control | Omron-JAPAN |

6. | PLC | Siemens-Germany |

7. | Touch screen | Siemens-Germany |

8. | Contactor | Schneider-France |

9. | Sensor | BANNER-Germany |

10. | Pneumatic components | FESTO-Germany |

11. | Sliding bearing | Igus-Germany |

12. | Cap unscrambler motor | FEITUO |

13. | Conveyor motor | FEITUO |

14. | Solenoid valve | Japan SMC |

15. | Air cylinder | Japan SMC |

16. | Pressure regulation valve | Japan SMC |

17. | Intermediate relay | Schneider -France |

18. | Transformer | China |

19. | Pneumatic | Japan -SMC |

20. | A. C. contactor | Schneider |

By continuing to use the site you agree to our privacy policy Terms and Conditions.