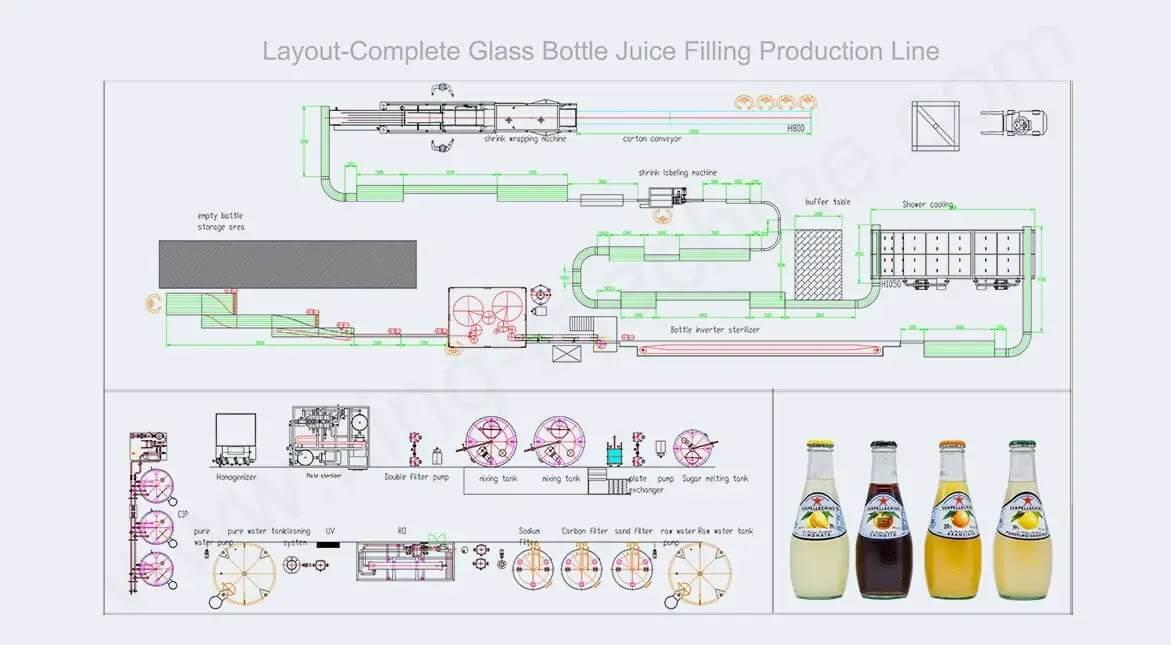

Application: juice, beer, carbonated sodt drink, soda water, sparkling water, alcoholic drinks, wine, etc. Suitable for: glass bottles Filling system: gravity filling Production capacity: 3,500BPH (500ml)

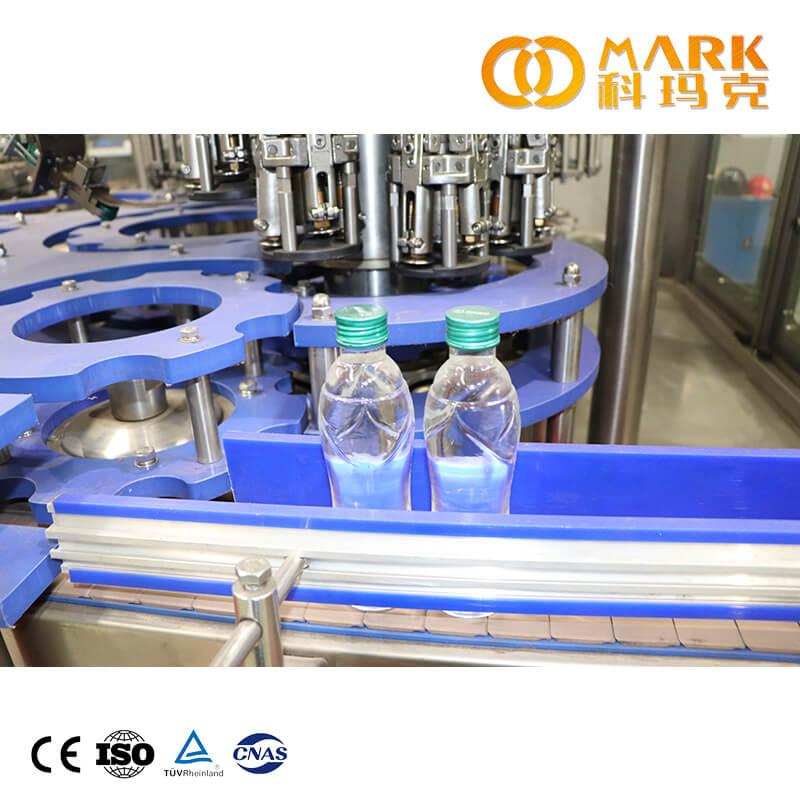

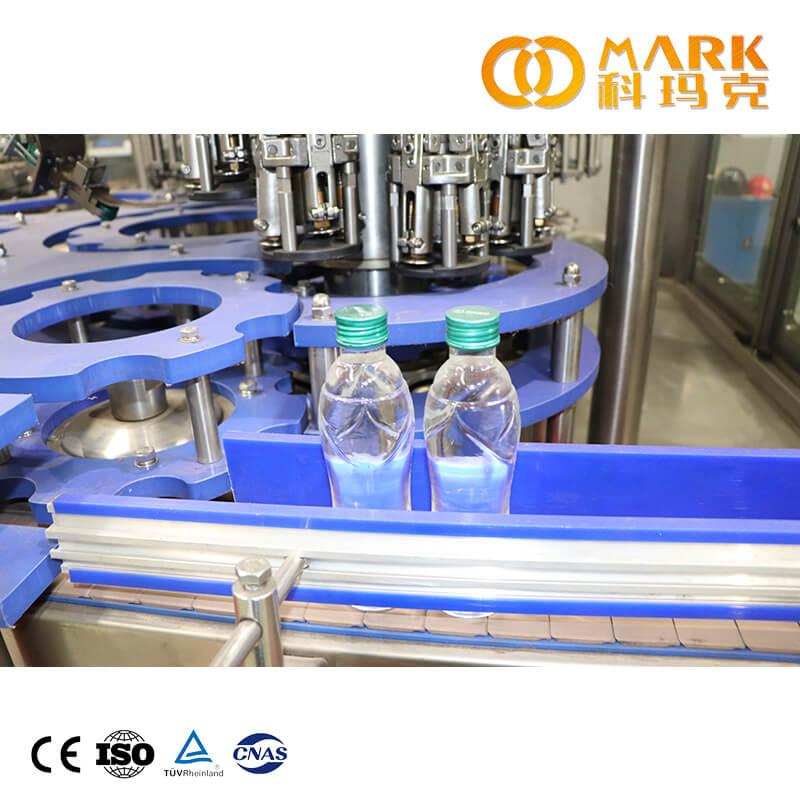

This machine has washer,filler,capper three functions in one body, it is automatic in total process and suitable for PET bottled water without gas.The total machine uses advanced photoelectric detection technology to detect each parts operation status, no bottle no filling, and no bottle no capping, automatic and easy operation.

3500 BPH For 500ml Glass Bottle Juice Filling Machine

Glass bottle water filling for glass bottle integrates the function of rinsing, filling and capping together. Based on advanced technology overseas, and designed according to room filling processing demands of non-carbonated water and alcoholic drinks to be one of the advanced room filling production line.

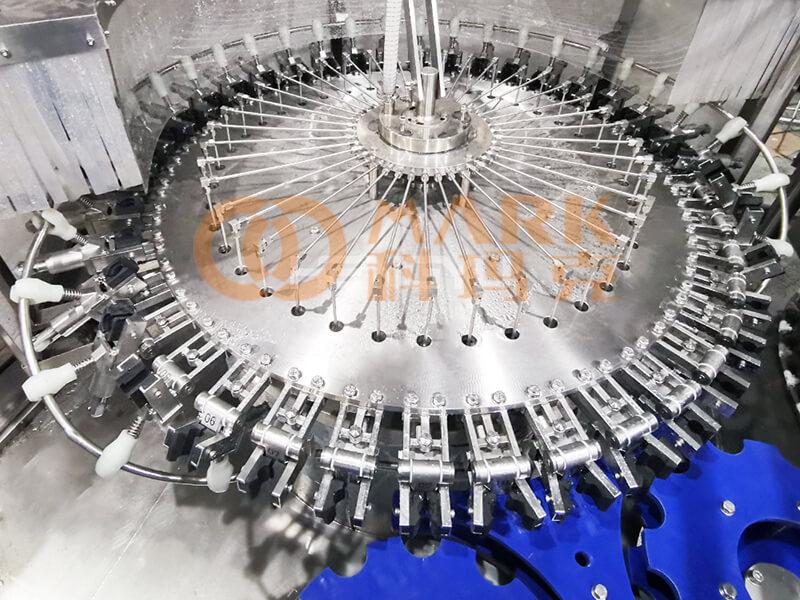

| Washing heads - Into bottle way is air conveyor direct connection with bottle dial. - All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean. - 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing. - 304/316 stainless steel washing pump make the machine more durable. |

Filling heads - 304/316 Stainless steel high precision filling nozzle - Filling volume adjustable in fine rank, same liquid level after filling - All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean - 304/316 stainless steel filling pump - Efficient spray nozzle rinse thoroughly and save water for flushing |  |

| Capping heads - Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping - All 304/316 stainless steel construction - No bottle no capping - Automatic stop when lack of bottle - Capping effect is stable and reliable, Defective rate ≤0.2% |

Main Features

Main Features

1. Touch screen operation interface.

2. Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash.

3. The filling accuracy can reach ±0.2%.

4. With no bottle no flling and automatic bottle stop function.

5. Design different positioning devices according to the actual situation of the bottle.

6. PLC programmable control use Japan Mitsubishi.

7. Material contact parts are made of SUS304# stainless steel.

-Technical Parameters-

Model(BCGF) | 14/12/5 | 18/18/6 | 24/24/6 | 32/32/8 | 40/40/12 | 50/50/12 | 60/60/15 |

Washing heads | 14 | 18 | 24 | 32 | 40 | 50 | 60 |

Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 |

Cappping heads | 5 | 6 | 6 | 8 | 12 | 12 | 15 |

Capacity(BPH) | 2000 | 3500 | 5000 | 8000 | 12000 | 16000 | 20000 |

Power(kw) | 2.2 | 3.5 | 4.5 | 6 | 7.5 | 9.5 | 11.2 |

Dimension(mm) | 2400*1600*2500 | 2600*1920*2550 | 3100*2300*2800 | 3800*2500*2900 | 4600*280082900 | 5450*3300*2900 | 6500*4500*2900 |

Weight(kg) | 2500 | 3500 | 4500 | 5600 | 8500 | 9800 | 12800 |

OPP Hot Melting Labeling Machine

OPP Hot Melting Labeling Machine

OPP plastic labels are non-toxic, environment protecting, and look nice and attractive. The technological development of label is rapid. Including o indicating the brand, composition and shelf life, the developers are now working to develop product packaging of low-cost, impact resistance and strong attractive appearance. With the new technology development of shrink packaging system and the emergence of underlying and adhesive of shrink labels, the roll label material OPP plastic label technology provides the processors with a labeling process of low cost, nontoxic and environment protection, low feed consumption and high resolution.

Automatic PE Film Shrink Wrapping Machine

(1)350/500/550/600ML

large package: 4*6, 4*5

Small package: 3*4, 3*5

(2)1L/1.5L/2L/2.5L

large package:3*3,3*4 Small Package:2*2,2*3beverage machinery

High efficiency and stability, simple operation.

PLC control, quality assurance.

By continuing to use the site you agree to our privacy policy Terms and Conditions.