carton packging machine include carton unpackaging machine and carton packaging machine and carton sealling machine

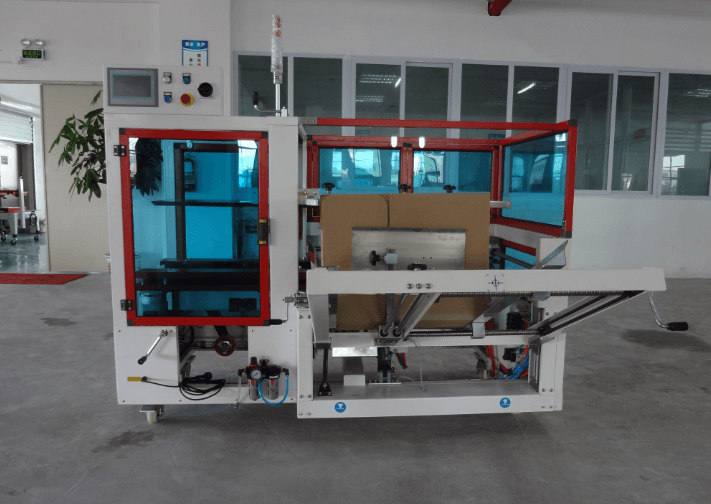

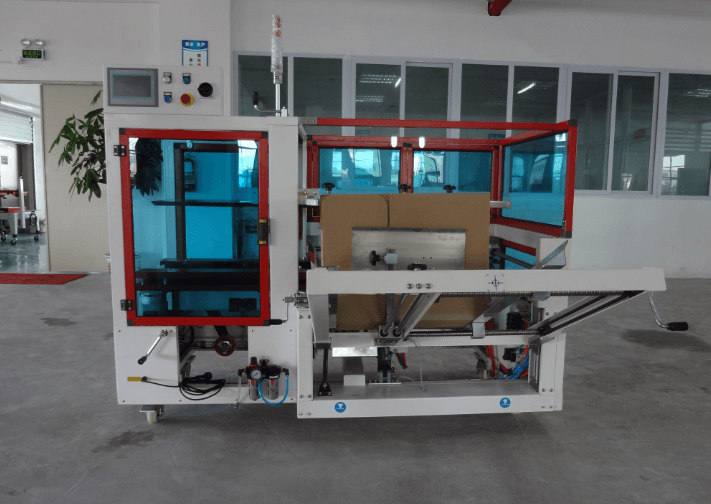

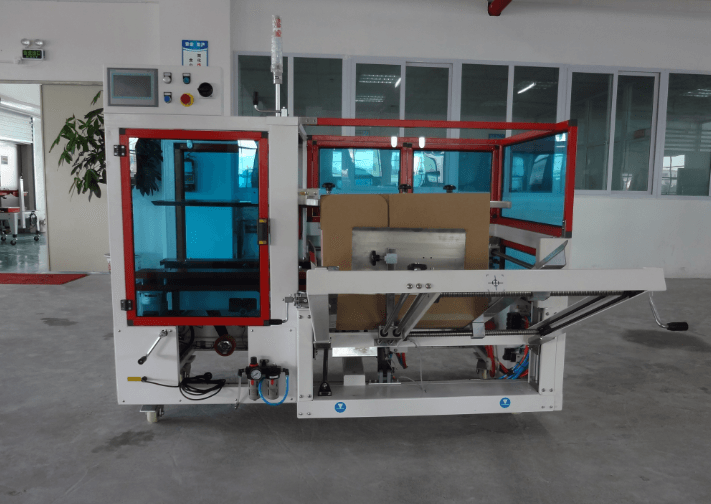

1 Automatic unpacking machine

1. Power supply: 220V 50Hz 800W

2. Air pressure: 6kg / cm2

3. Air consumption 200L / min

4. Overall dimension of the machine: l2160 * w2080 * h1492mm

5. Machine weight: 400kg

6. Belt width: 4.8-7.2cm

7. Speed: 10 boxes / min

8. Features of the whole machine:

The design and manufacture of the equipment shall meet the requirements of the production line process and plane layout, with beautiful appearance and good manufacturing process

Low power and water consumption, simple and quick operation, adjustment and maintenance

The machine has good self safety protection functions, such as overload protection and safety door, etc

Whether there is tape or cardboard box alarm function

Box storage mechanism: about 50 unformed cartons can be placed at a time (depending on the thickness of the cartons), and can be supplemented at any time

9. Workflow: suction box - unpacking - folding front and rear paper covers - folding left and right paper covers - sealing bottom

10Environmental conditions: humidity ≤ 98%, temperature 0-40 ℃

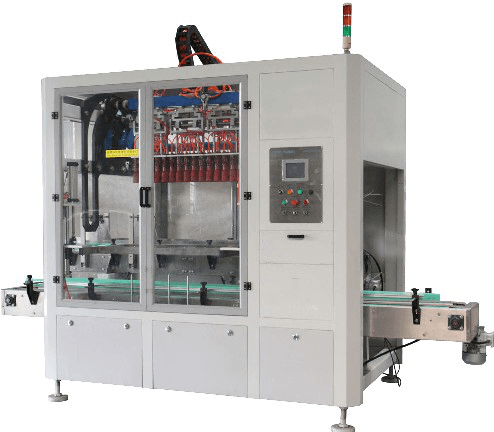

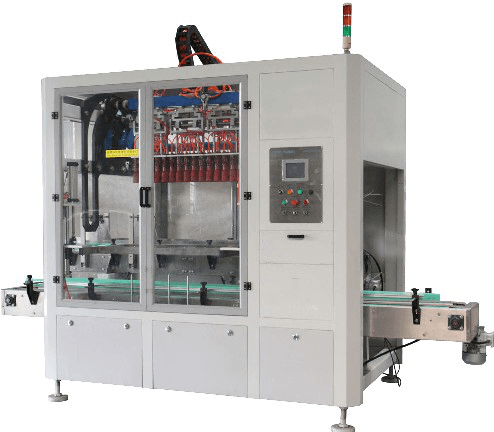

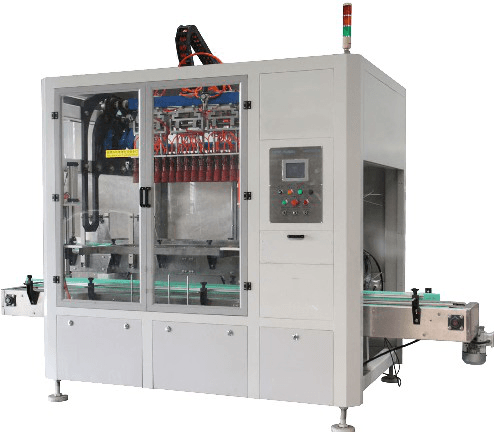

2 . Automatic packing machine

A. Packing machine structure:

1. Separate conveyor train (including conveyor)

a. 1 conveyor

b. 1 set of blocking mechanism

c. 1 set of the whole row of grooves

d. Push in mechanism 1 set

2. Carton conveying positioning mechanism

a. Block mechanism 1 group

b. 1 carton conveyor

3. Packing mechanism

a. Product installation organization

b. Electronic control system

B. Organization configuration description

1. Conveyor train

Frame: carbon steel material, surface spray plastic treatment

Chain plate: module net, plastic steel material

Outrigger: carbon steel, surface spray plastic treatment

Speed: variable frequency speed regulation

Round cap guardrail: U-shaped stainless steel groove and ultra-high molecular polyethylene protective strip

Branching mechanism: stainless steel plate, surface wire drawing treatment

2. Empty box conveyor

Body: carbon steel material, surface spray plastic treatment

Speed: adjustable

Round cap guardrail: U-shaped stainless steel groove and ultra-high molecular polyethylene protective strip

Barrier mechanism: stainless steel plate welding + cylinder

3. Packing machine

The automatic packing machine is an intelligent full-automatic packing machine, which can automatically sense after packing, discharge the cartons and send them to the sealing machine.

The machine is controlled by PLC + touch screen. It is equipped with a bottle missing alarm shutdown and a safety device for no bottle and no packing. The assembly line is greatly convenient for operation, management and reduction of production personnel and labor intensity. It is an indispensable equipment for automatic scale production.

According to the packing requirements, the products can be arranged automatically.

Novel design and compact structure.

It can be applied to a wide range of products.

It is especially suitable for use with packaging assembly line and convenient to move.

PLC program control, simple operation, stable action.

3、 Automatic sealing machine

Body material: the whole body is welded with high-quality carbon steel, and the surface is sprayed with plastic

Power supply: 220V, 50Hz, 400W

Working air pressure: 4kg / cm2

Overall dimension: l1700 * W830 * h1450mm

Platform height: 600-750mm (adjustable)

Machine performance:

Automatic folding at the top, automatic and timely transportation, no need of manual supervision, suitable for connecting the full-automatic production line

Electrical configuration:

- contactor: Schneider (France)

- push button switch: Schneider (France)

- pneumatic components: adek (Taiwan)

Motor: Liming (Taiwan)

Working noise: ≤ 80dB

Environmental conditions: humidity ≤ 98%, temperature 0-40 ℃