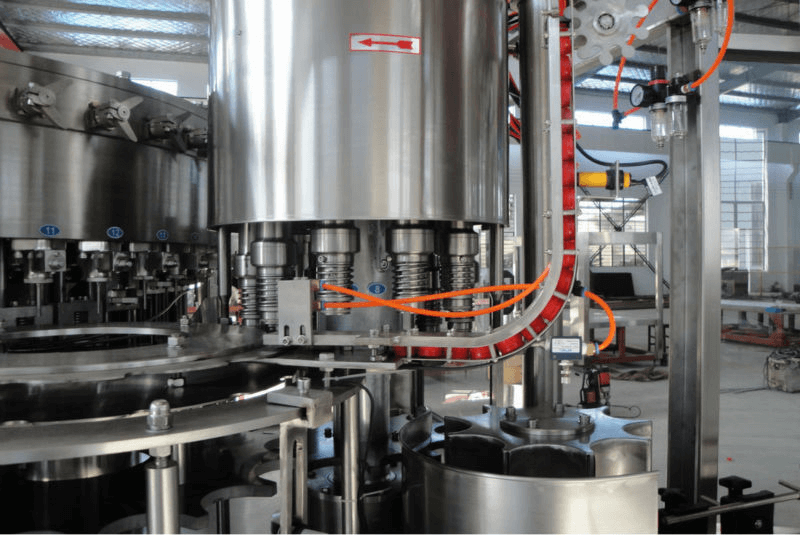

Small Flavored Water Production Line Manufacturing Plant 1. RCGF32-32-8 bottling machine 2. Automatic washing filling capping 3 in 1 3. SS304 stainless steel 4. SIEMENS programmed controller (PLC) 5. ISO9001, CE, SGS, BV, SONCAP

Application: juice, milk, vitamin drinks, functional beverage with particles, flesh, pulp, fruit pieces, etc.

Suitable for: PET bottles with all volumes and shapes

Filling system: 10,000 BPH For 500 Ml Juice Plant Manufacturer Juice Factroy Machine

Production capacity: 2,000BPH–20,000BPH (500ml)

Technical characteristics

1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing

pump.

2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder.

3. Capping system: Combined with capper, cap sorter and cap falling track.

4. Driving system: Combined with main motor and gears.

5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates.

6. Electrical controlling system: this part is frequency inverted, PLC controlled and touch screen operated.

washing part

1. All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

2. 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

3. 304/316 stainless steel washing pump

filling part

1. 304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, inside mirror polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

5. UFO Type filling tank, it is easy for CIP washing

capping part

1. Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2. All 304/316 stainless steel construction

3. No bottle no capping

4. Automatic stop when lack of bottle

configuration

1. Material of filling valve: Stainless steel 316L available

2. Material of rotary tray and machine platform of rinser and filler: Stainless steel 304.

3. Main motor: ABB/SEW (Germany)

4. Sliding bearing: Igus (Germany)

5. Frequency inverter: MITSUBISHI (Japan)

6. Touch screen: DIGITAL (Japan).

7. PLC: MITSUBISH (Japan)

8. Pneumatic components: FESTO (Germany)

9. Seals: Busak+Shamban (USA)

10. Photocell switch: BANER (USA).

11. Proximity switch: TURCK (Germany).

machine parameter

| Model | RCGF14-12-5 | RCGF18-18-6 | RCGF24-24-8 | RCGF32-32-8 | RCGF40-40-10 | RCGF50-50-15 |

| Capacity | 3000-4000 | 4000-6000 | 8000-10000 | 12000-14000 | 16000-18000 | 20000-24000 |

| Height | 150-320 | |||||

CAP | Plastic Screw Cap | |||||

Power (kw) | 4.23 | 5.03 | 6.57 | 8.63 | 10.68 | 12 |

Size (mm) | 2230*1630*2250 | 2360*1830*2250 | 2900*2200*2250 | 3880*2200*2250 | 3700*3000*2350 | 4500*3300*2350 |

Weight (kg) | 2200 | 2500 | 4200 | 6000 | 7000 | 9000 |

By continuing to use the site you agree to our privacy policy Terms and Conditions.