Now more and more fruit juices have appeared on the market, there are fermented fruit juices, fresh juice, contentrated jucie. Here Comark give you a detailed introduction of the production equipment and production process.

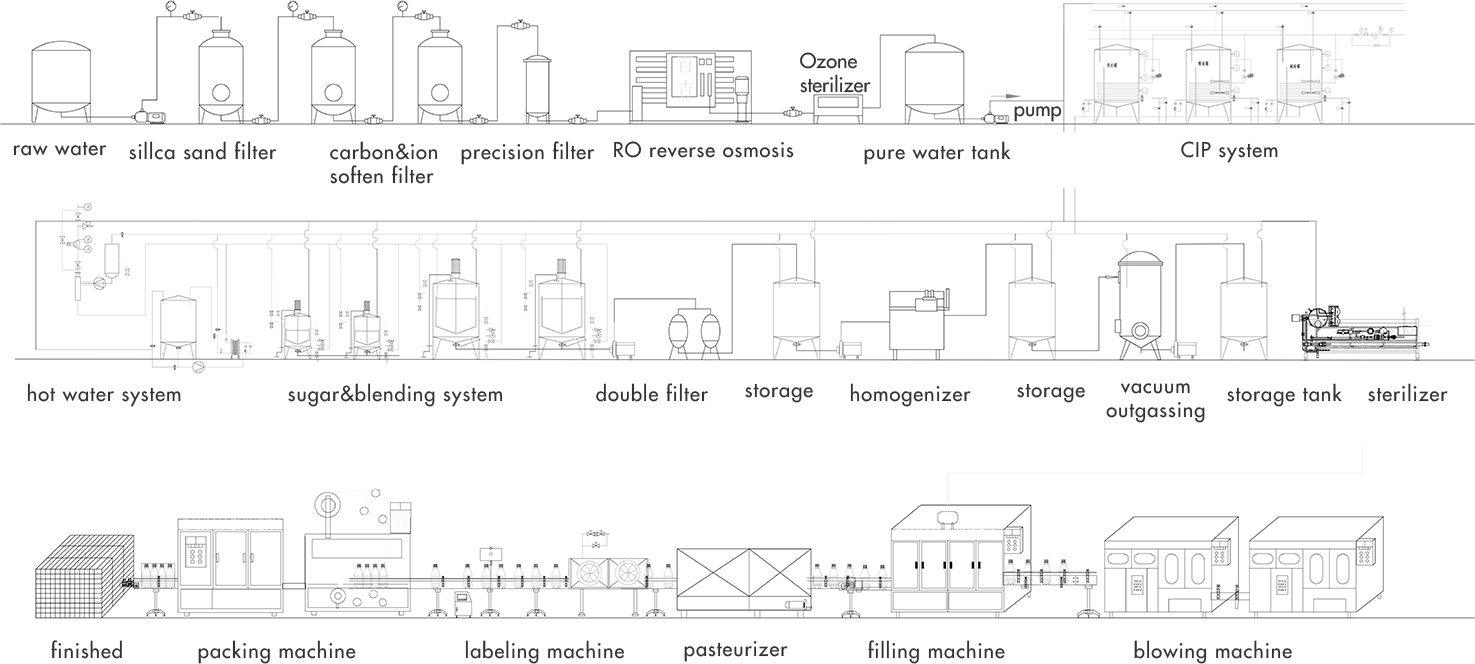

From the beginning of the preparation, the first choice we need is sugar melting, filtration, cooling, preparation, sterilization, homogenization, purified water, bottle washing, filling, cap disinfection, screw cap, warm bottle, automatic coding, inspection, labeling, packing , sealing, palletizing, warehousing. After this set of technological processes, the production of fruit juice beverages has been completed, and it can be tested and marketed.

The first step of the equipment used must be the sugar melting tank, and the next step is the double bag filter to avoid large particles of sugar from entering the production line. It needs to be cooled to enter the production line, and a plate heat exchanger is used. To enter the mixing tank, we need to use a double tube filter to continue filtration. After filtration, we also need to sterilize it. The sterilization temperature is usually 121 ℃ to 135 ℃, and there are two options: plate type and tube type. After that, the juice beverage is homogenized. At this time, the juice beverage is ready, and the next step is the filling part.

The prepared juice needs to be filled, and a filling machine is needed. Now, three-in-one filling machines are generally used. The cover has three functions in one, and also avoids the intervention of dust and other impurities during the filling process. Comark can customize a variety of capping machines according to customer needs and market needs. Such as sports cover. Our juice filling is generally hot filling. At this time, a warm bottle is used to achieve a constant temperature to ensure that the subsequent packaging can be successfully completed.

After that, we will have laser coding and ink coding for customers to choose. Regarding bottled juice, two kinds of labels, opp and pvc are usually used. The opp label itself will be cheaper, but the machine will be much more expensive, which is suitable for large-volume production lines; pvc labeling machine is cheaper but the label cost is higher, more suitable for small production line. Finally, we come to our packaging, usually in two forms of carton packaging and film packaging, we can choose according to cost and local market demand.

With such a set of equipment, our juice beverages can be listed, and finally in your hands, you can drink safe and hygienic juice beverages.

Comark is a manufacturer of juice beverage production equipment and water treatment equipment. We can tailor the production equipment you need. In addition, we can also help design labels and bottle shapes. Welcome to contact us at any time if you are interested in bottle juice.